At Road Science, sustainability isn’t a side project - it drives how we design, manufacture, and deliver products for New Zealand’s road network. For more than a decade, we’ve partnered with organisations such as the Energy Efficiency and Conservation Authority (EECA) and the Sustainable Business Network to continually improve energy efficiency, reduce waste, and accelerate the transition to cleaner, safer industrial practices.

Electrifying process heat: a game‑changing milestone

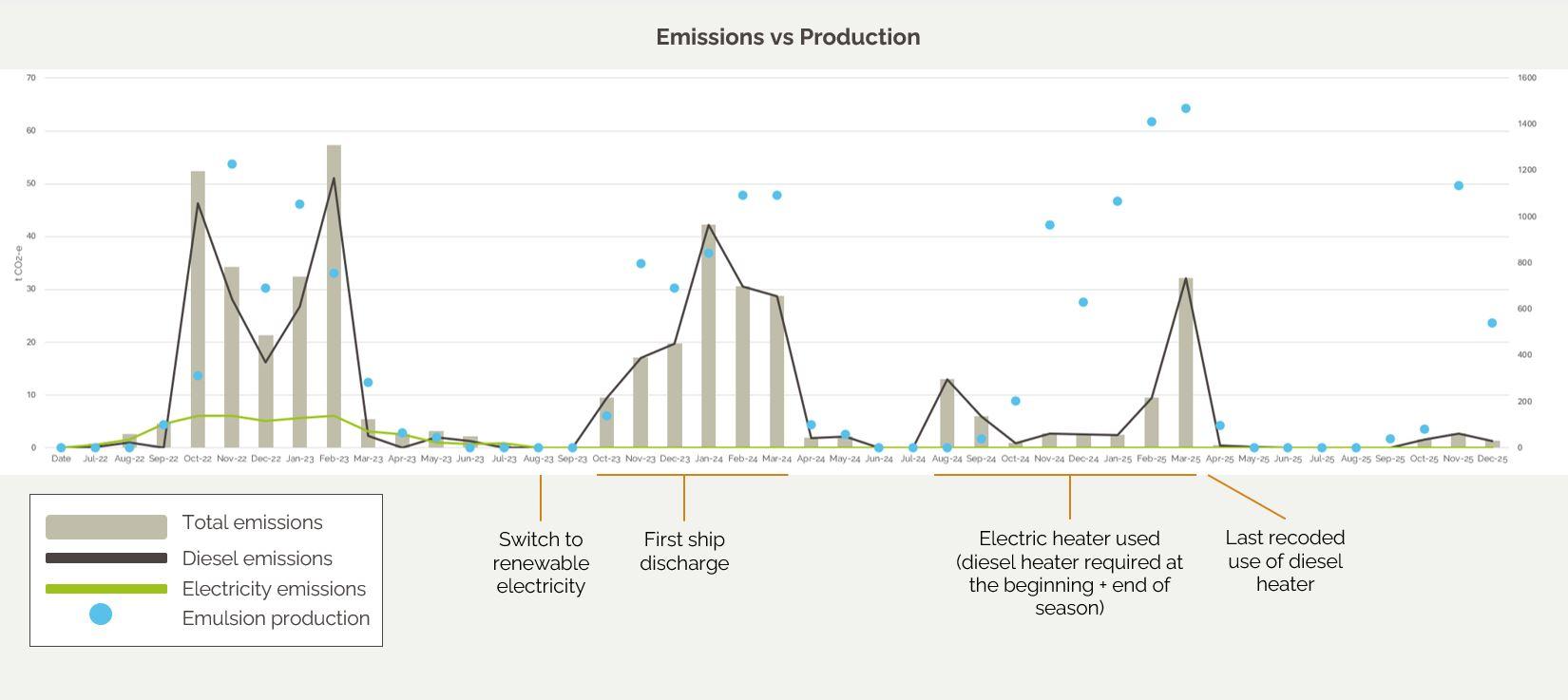

In 2023, we began one of our most significant decarbonisation shifts yet: electrifying process heat in bitumen manufacturing. At our Bluff bitumen plant, we installed a hybrid electric heating system and transitioned to 100% renewable electricity. As a result, the site now operates with 0 kg CO₂‑e scope 2 energy emissions - a first for our industry and a major step towards fossil‑free bitumen production. Diesel use has dropped to near zero, improving local air quality and creating a safer, cleaner work environment.

This breakthrough proves that high‑temperature bitumen processing can run efficiently and reliably on renewable electricity, providing a scalable model for other Road Science sites and various other sectors.

Low‑carbon infrastructure in practice

Our commitment extends across our network, including the construction of a fully electric bulk bitumen tank at Lyttelton - designed in collaboration with Energy NZ - which avoids an estimated 209 t CO₂‑e emissions per year compared with traditional diesel‑fired systems.

Transforming an entire industry

By openly sharing our learnings and working with customers, engineers, regulators, and industry partners, Road Science is helping reshape how New Zealand approaches high‑energy industrial operations. The result is clear: lower emissions, lower energy costs, reduced environmental impact, and a future‑ready supply chain for the road construction sector.

We’re not just reducing emissions - we’re setting a new benchmark for sustainable infrastructure materials.

Read full Bluff bitumen plant energy emissions story here