Emulsion Stabilisation: The road to better repairs with EnviroBase

15 April 2025

Let’s be honest—road repairs can feel like a never-ending game of whack-a-mole. You fix one pothole, and before you know it, another one’s popped up down the road. According to a NZTA Research Report, on average, traditional cement-stabilised patches last three years, meaning more roadworks, more detours, and more frustrated drivers. Surely, there’s a better way?

But first, what’s a patch repair anyway?

A patch repair is exactly what it sounds like—a fix for road defects like potholes, cracks, and ruts. Whether it’s a quick band-aid job or a long-term solution, the goal is to keep roads smooth, safe, and up to the job. But here’s the problem: old-school cement-stabilised patches often call it quits too soon, leaving roads worse for wear and crews stuck in an endless loop of repairs. A key contributor to this patch-on-patch practice is a failure in waterproofing.

The waterproofing problem: Why our roads fail early

Water is a leading cause of road deterioration in New Zealand. While our roads perform well under dry conditions, this is an ideal scenario, and waterproofing quickly becomes a critical issue. Water seeps into roads through surface defects or inadequate drainage. Research from NZTA found that water can even be forced through a first coat chip-seal layer under pressure from passing vehicles (NZTA, 2009). As a result, waterproofing issues are widespread, with 30-40% of reseals due to flushing —a defect that occurs when water gets trapped in the pavement and evaporates, creating pressure beneath the road surface. Under our Kiwi summer sun, this process accelerates, turning our roads into a sticky, deteriorating mess.

Early failure on cement-stabilised patches

While cement patches are commonly used due to low cost, they are rigid, and many New Zealand pavements are not designed to support such a stiff upper layer. Cement cracks under stress and doesn’t stand up well to moisture, leading to early failure.

Here are a few analogies:

- Shrinkage Cracking - Dried mud:

When mud dries, the water loss results in a change in volume, shrinkage of the mud and cracking on the surface. It’s the same for cement-stabilised patches. The reaction that creates cement bonds uses available moisture leading to shrinkage and the development of shrinkage cracking. - Fatigue and fatigue cracking – Sheet of glass on a trampoline:

When glass is placed on a trampoline, it is rigid and stiff, while the trampoline is flexible. Now, if we put a weight in the middle of the glass, what happens? Without suitable underlying support, the glass will experience excessive flexure and is at risk of cracking.

It’s the same for cemented patches. In a lot of cases, the cemented layer is significantly stiffer than the underlying material. The lack of underlying support results in excessive flexure and the development of cracking. With repeated traffic loading, the material weakens, the cement bonds are broken, and the material reverts to an unbound layer. (NZTA, 2013, CAPTIF).

- Reflection of cracking – Paint on a cracked wall:

If a wall develops cracks, the cracks break through the paint to the surface. It’s the same for cemented patches. Cemented patches lack surface cover, which means that when cracking develops from shrinkage or fatigue, the cracking will be reflected through the seal layer to the surface compromising waterproofing.

The importance of mitigating the impact of water

When aggregate (a crucial element in road composition) is saturated, water occupies the space between the particles. Water is incompressible and prevents the aggregate from locking together, erodes fine particles, and reduces the inter-particle friction and strength. The result? Roads that don't last. So, how can we stop water from wreaking havoc?

Emulsion stabilisation: The game-changer in pavement repair

Introducing EnviroBase by Road Science — an innovative emulsion stabilisation solution to water, cracking, and fatigue issues. With the emulsion stabilisation of EnviroBase, pavements become more durable, resilient, and stable, even under wet conditions. Networks that have used emulsion stabilisation have seen rework rates drop by 95%. For the average driver, this means smoother rides and less disruption due to road works. To understand the emulsification process, check out our Head of Product Innovation, Darcy Rogers explain it with hollandaise sauce!

THE SCIENCE BEHIND ENVIROBASE

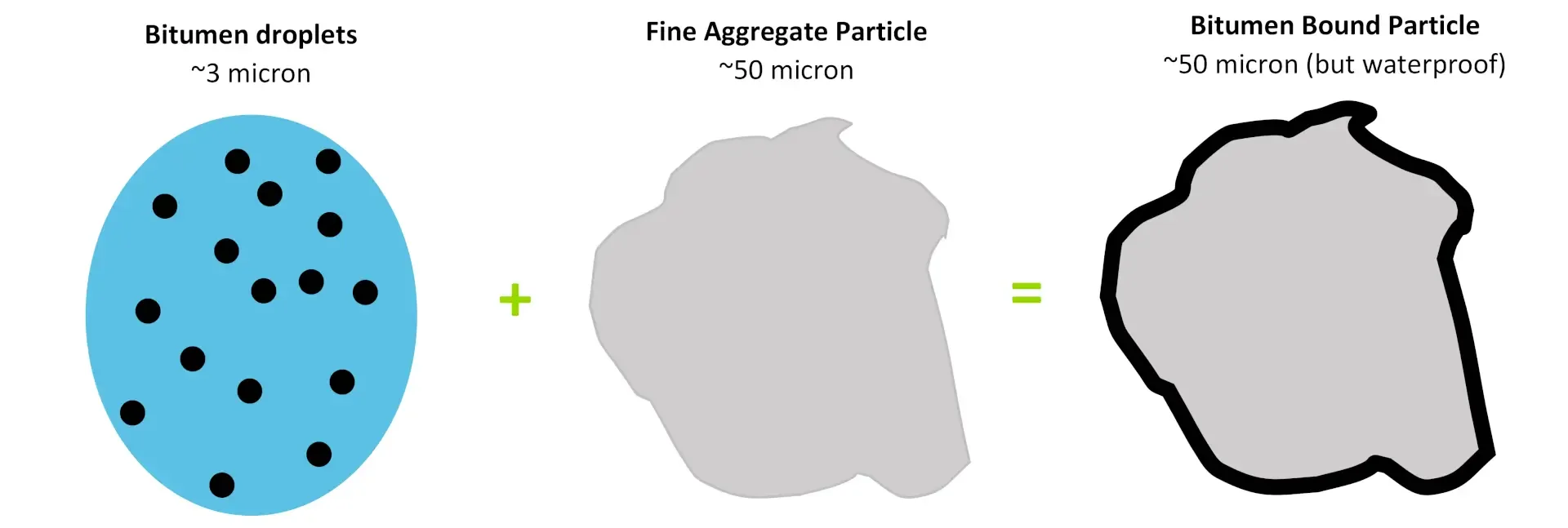

EnviroBase has been designed to target the fine aggregate particles. Emulsifying bitumen in a water phase gives bitumen significant surface area which enables it to effectively coat the fine aggregate in bitumen. When combined with aggregate, the emulsion breaks, separating the bitumen and the water. The water is absorbed into the aggregate and the bitumen droplets recombine, binding the fines. The bitumen occupies the void space and binds the fine particles of the aggregate together. Preventing water from reducing the inter-particle friction.

Lab Performance

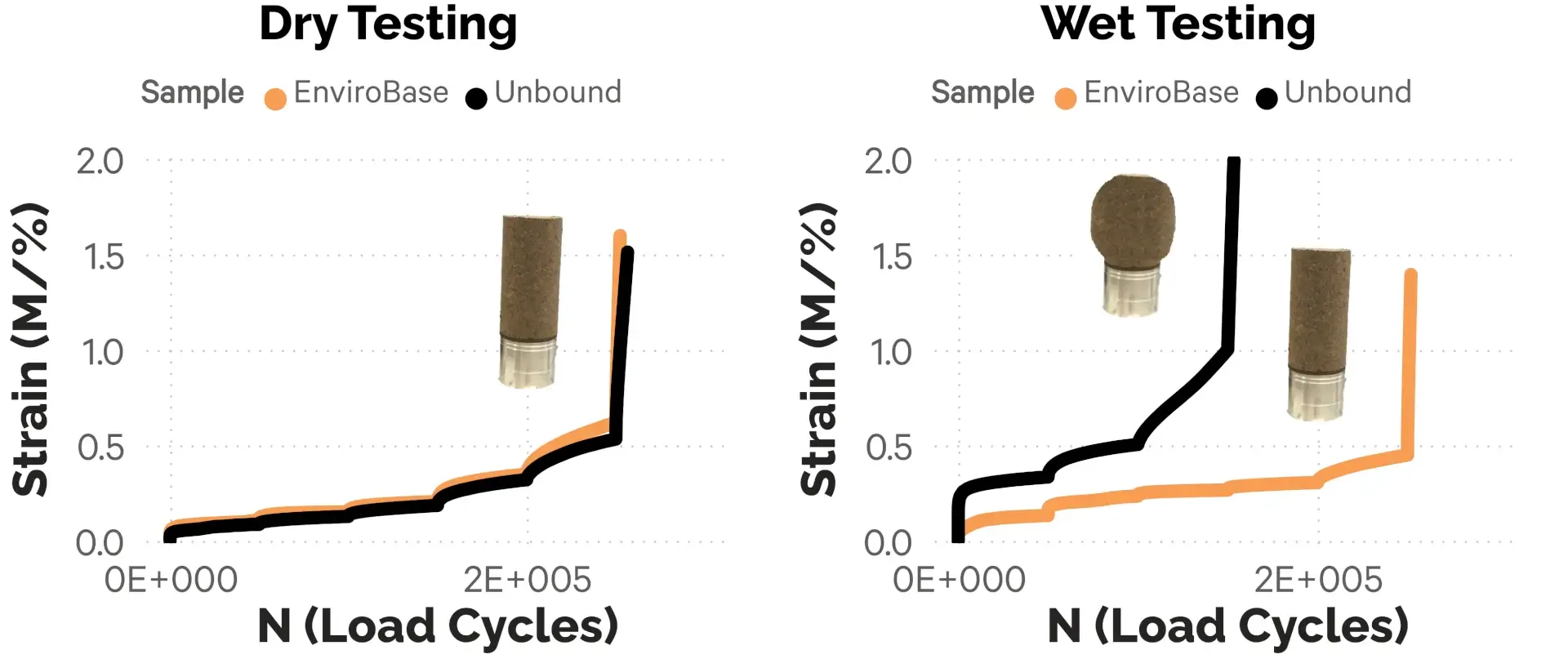

To understand the effectiveness of waterproofing under simulated traffic loading, repeated load triaxial (RLT) of aggregate samples was performed in both wet and dry conditions. The output from an RLT test is permanent strain, which is the percentage change in sample height. This is indicative of the rutting resistance of a sample, EnviroBase outperforms traditional cement in wet conditions, yet cement is stronger in dry but for the reasons in the early failure section, our roads don’t stay dry, so wet conditions are more like the norm.

- A good result will look cylindrical with little change in shape. The material has resisted the load.

- A poor result will look like a barrel. The material had poor resistance to the load and has deformed.

Two samples were tested, an unbound base course and an emulsion-stabilised (EnviroBase) base course:

- Dry testing: The two samples performed almost identical. There is a similar deformation between the samples.

- Wet testing: The EnviroBase sample significantly outperformed the unbound sample. The unbound sample significantly deformed and the EnviroBase sample performed almost identically to the dry test.

EnviroBase has maintained rut resistance in all moisture conditions. Lab testing highlights the waterproofing capabilities of EnviroBase, however we thought we would push it to the limits with a water blaster!

NETWORK PERFORMANCE

RAMM Maintenance data from several local authorities and state highway contracts has been analysed to better understand the performance of stabilised patches out on the network. The first patch occurring on a road has been identified along with any subsequent maintenance on the patch within the first year of service.

- The number of patches failing is used instead of m2 of patches

- Potholes are excluded as they can inflate the rework rate - multiple potholes are often recorded within a single patch. Additionally, their location data tends to be more varied compared to other fault types

- The data is current up to 28th of February 2025

Historical trends on cemented patches

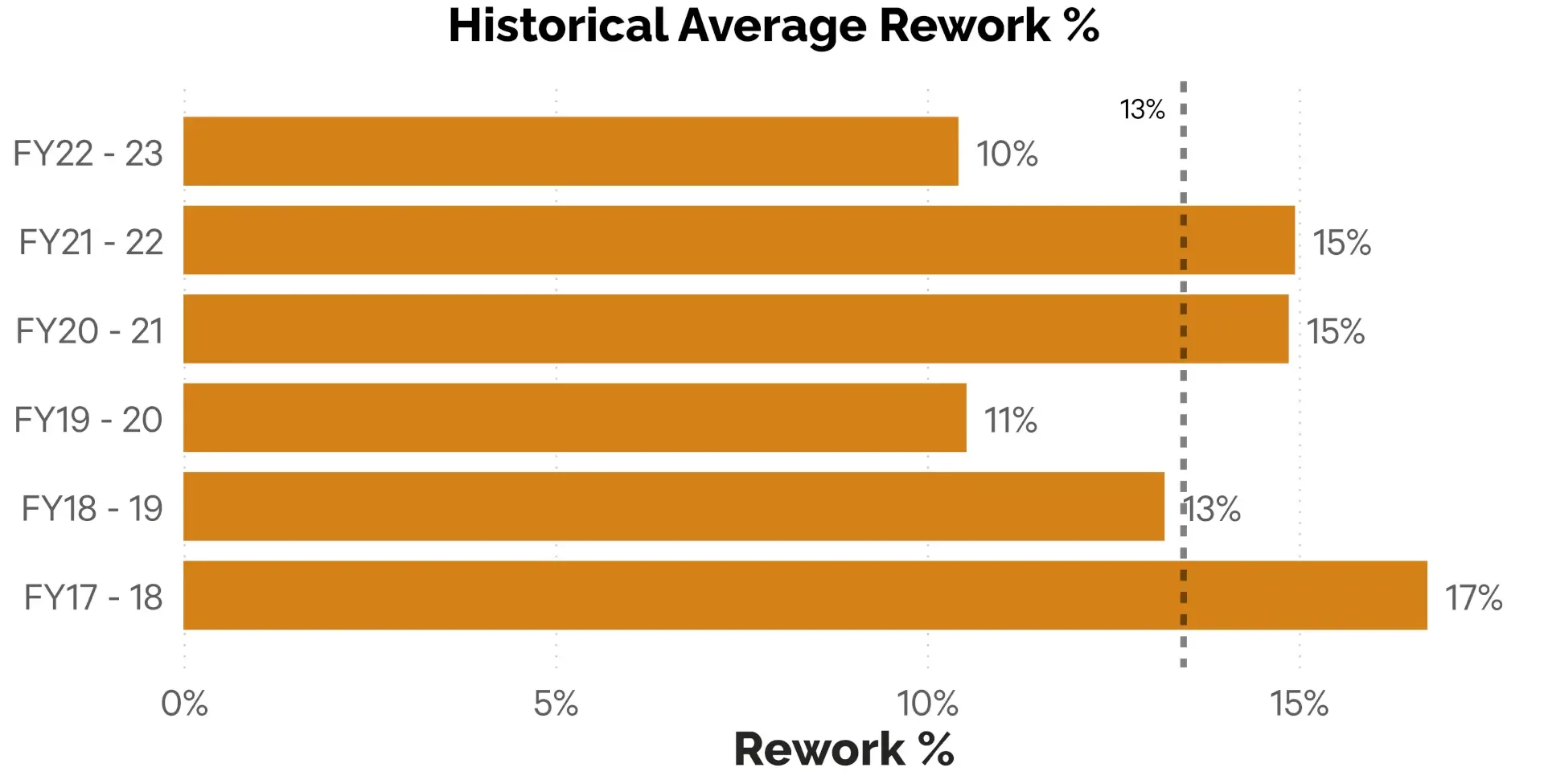

There has been an average of 13% rework rate within the first year using cement-stabilised patching.

Plotting the distribution of the average rework time over six years reveals a critical trend: a significant portion of failures occur within the first 28 days. In fact, almost one in five cement patches that fail within a year do so within this initial period, highlighting an early-stage vulnerability in the material or application process.

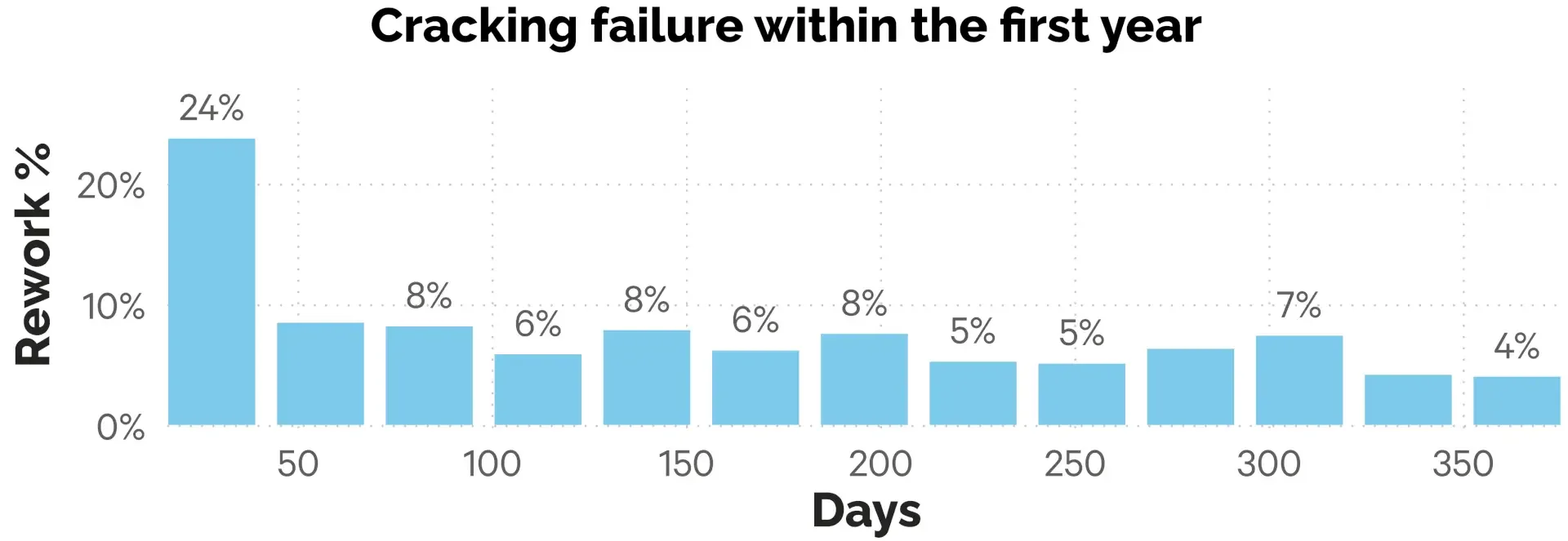

Analysing the distribution of fault types over the first year reveals another notable pattern: cement-stabilised patches face the highest risk of cracking shortly after construction. In fact, 24% of all cracking failures within the first year occur within the first 28 days, likely due to shrinkage cracking as the material sets.

Similarly, early-stage deformation is a significant concern. Of all deformation failures recorded within the first year, 16% occur within the first 28 days. Given that patches are typically opened to traffic within a few hours of construction, the cement has limited time to strengthen and remains vulnerable — especially if exposed to rainfall. This early susceptibility underscores the need for improved performance early in a patches life.

Early-stage patch performance

The change in rework rate is analysed separately for each network to account for variability in network pressures. This macro-level analysis acknowledges the presence of multiple uncontrollable factors. By conducting network-specific assessments, we aim to minimise variations caused by differing external pressures, such as geographical conditions (e.g. geology, rainfall, and aggregate quality) and traffic patterns.

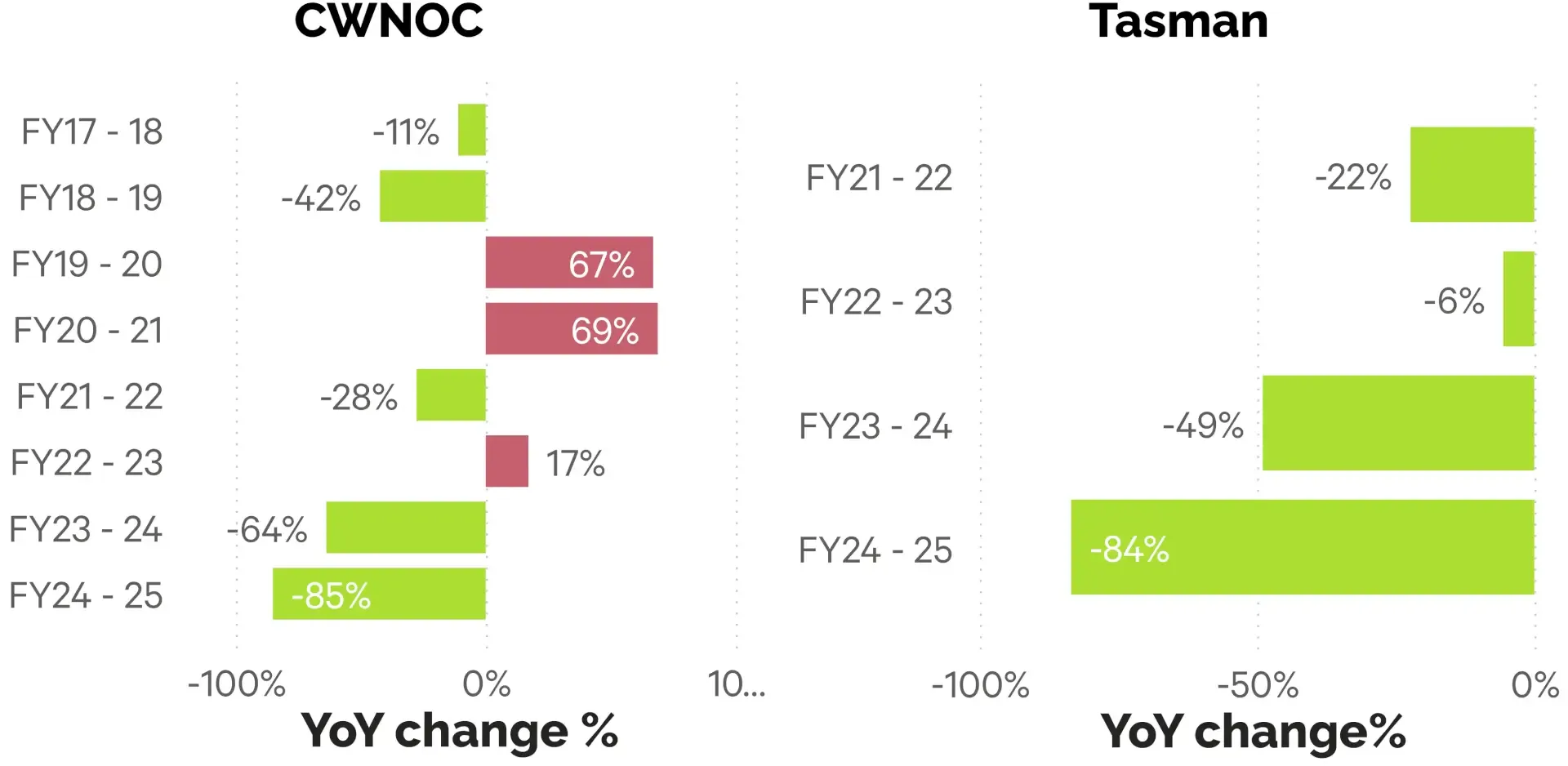

Notably, CWNOC and Tasman DC have demonstrated success with EnviroBase. The year-on-year rework rate trends, plotted below, show consistent improvements in both networks. Since the implementation of emulsion stabilisation, rework rates have steadily declined each year, highlighting the effectiveness of this approach.

NB; This analysis uses a two-year window - Year one accounts for initial patching and year two accounts for potential reworks occurring within a years' time. As such, FY23 - 24 and FY24-25 are not fully represented in the data set.

The implementation of cement and emulsion stabilisation on CWNOC has led to a significant 64% reduction in rework compared to the previous year, demonstrating the effectiveness of this combined approach. Similarly, Tasman DC experienced a 22% reduction in rework within the first year of adopting emulsion stabilisation, with continued year-on-year improvements.

CONCLUSION

Emulsion stabilisation represents a significant advancement over traditional cement-stabilised patching for pavement repairs. Cement-stabilised patches have historically suffered from early failures due to their brittle and rigid nature, which contributes to fatigue, cracking, and loss of waterproofing—factors that accelerate pavement deterioration.

EnviroBase, a bitumen emulsion stabiliser by Road Science, effectively mitigates these issues by maintaining pavement strength across varying moisture conditions while significantly reducing the risk of fatigue and cracking. Laboratory testing confirms the superior performance of emulsion-stabilised aggregates, particularly under wet conditions. Additionally, early network data supports its effectiveness, showing a substantial reduction in rework rates. While long-term data is still emerging, initial results strongly indicate that emulsion stabilisation enhances pavement durability, reduces maintenance needs, and offers a more resilient solution for patch repairs.

Converted to the positives of emulsion stabilisation?