Emulsion vs Cutback Bitumen

26 June 2019

An adhesion story

Early life failure as a result of poor adhesion of the binder to aggregate is often referred to as “stripping”. Stripping of aggregate from a chip seal can make up around 7% of failures occurring early in a seal’s life (within two years of application). Stripping, especially in early life can not only lead to resealing earlier than anticipated but also creates huge implications for the life expectancy. Repairs are different and can impact on future reseals with increased risk of flushing and bleeding.

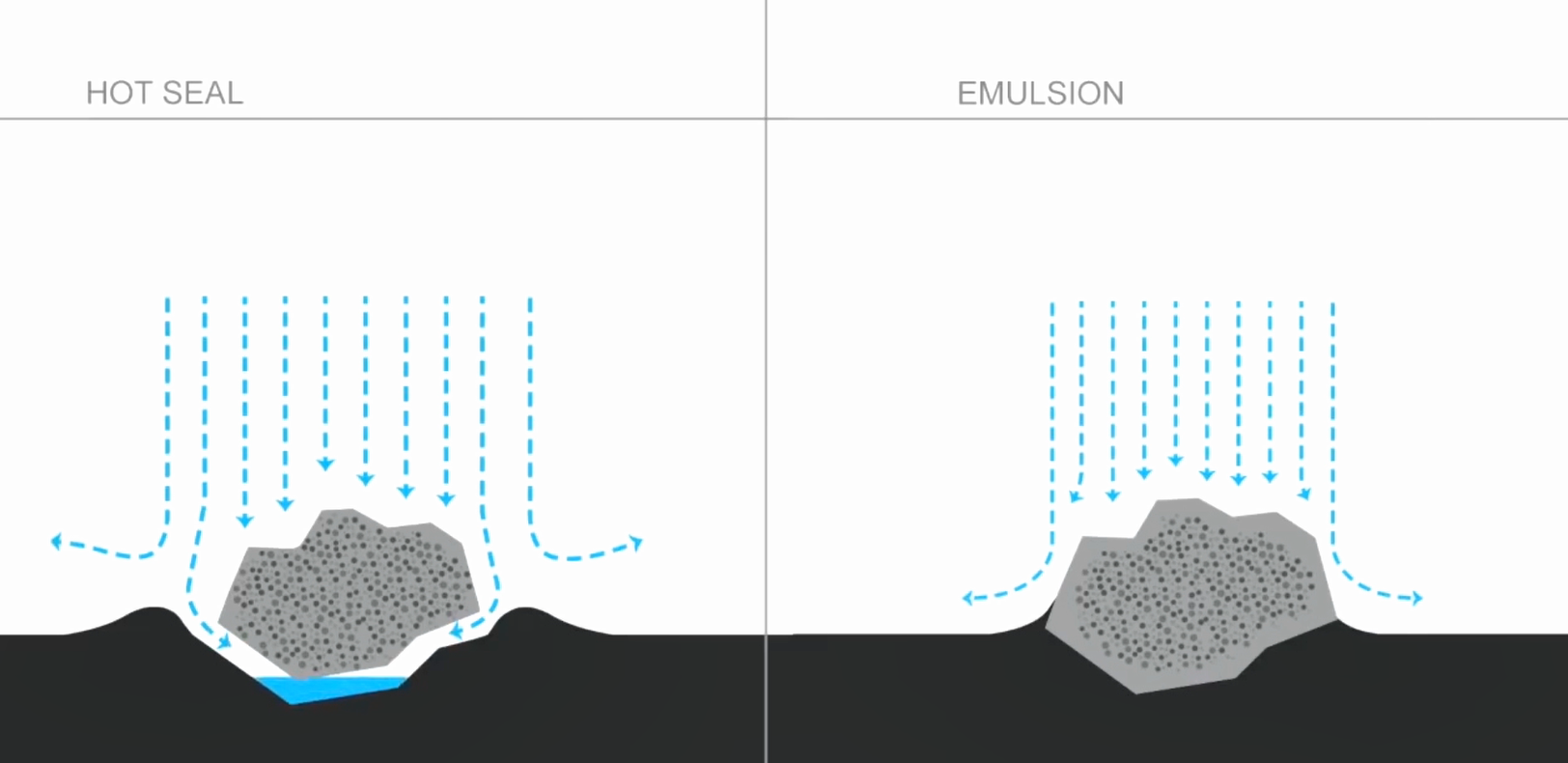

Early seal failures as a result of stripping are substantially reduced when emulsified bitumen is used. The superior wetting ability (the way the emulsion draws up and coats the chip) of the bitumen emulsion allows it to easily coat the aggregate allowing for much better early adhesion and reducing the likelihood of stripping. This is especially important during cooler weather when cutback bitumen viscosity and moisture content of aggregate can affect the ability for cutback bitumen to adhere to the aggregate. The superior adhesive properties of emulsions are also the reason that the majority to polymer modified chipseals are constructed using emulsion in New Zealand. The viscous nature of Polymer Modified Bitumen (PMB) inhibits good aggregate wetting and the risk of early stripping failure is high.

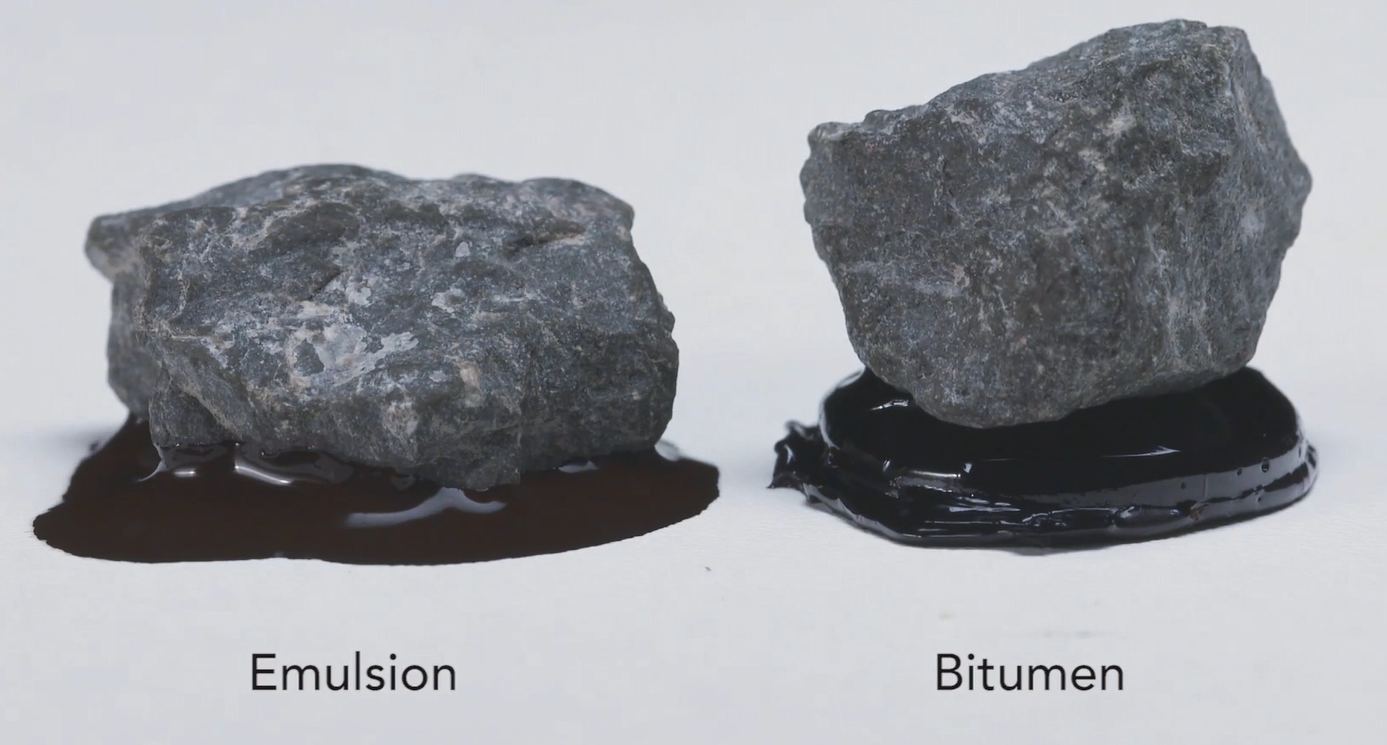

The images below show the difference between the contact area of binder with chip with both bitumen and emulsion. You can clearly see that emulsion easily wets the chip while the bitumen has only a very small amount of bitumen in contact with the aggregate. The bitumen will eventually gain a similar contact area but requires warm temperatures and traffic to help with this.

This lack of contact area allows water to get in under the chip, reducing adhesion and resulting in water induced stripping. This means that when sealing with cutback bitumen there is a period of time where the seal is prone to stripping because of rain or cold temperatures.

A review of seal failures from the 2017/18 sealing season has provided evidence to demonstrate that emulsion seals do experience less stripping. Results showed that the use of hot cutback bitumen resulted in a rate of 1.2% for remedial work, all of which was due to stripping. The primary cause of this was due to early rain or a sudden onset of cold temperature (or both). In the case of the emulsion seals this remedial rate halved to 0.6%. The greater adhesion of emulsion does not eliminate the need for good planning around weather but certainly reduces the impact of weather on the fresh seal.

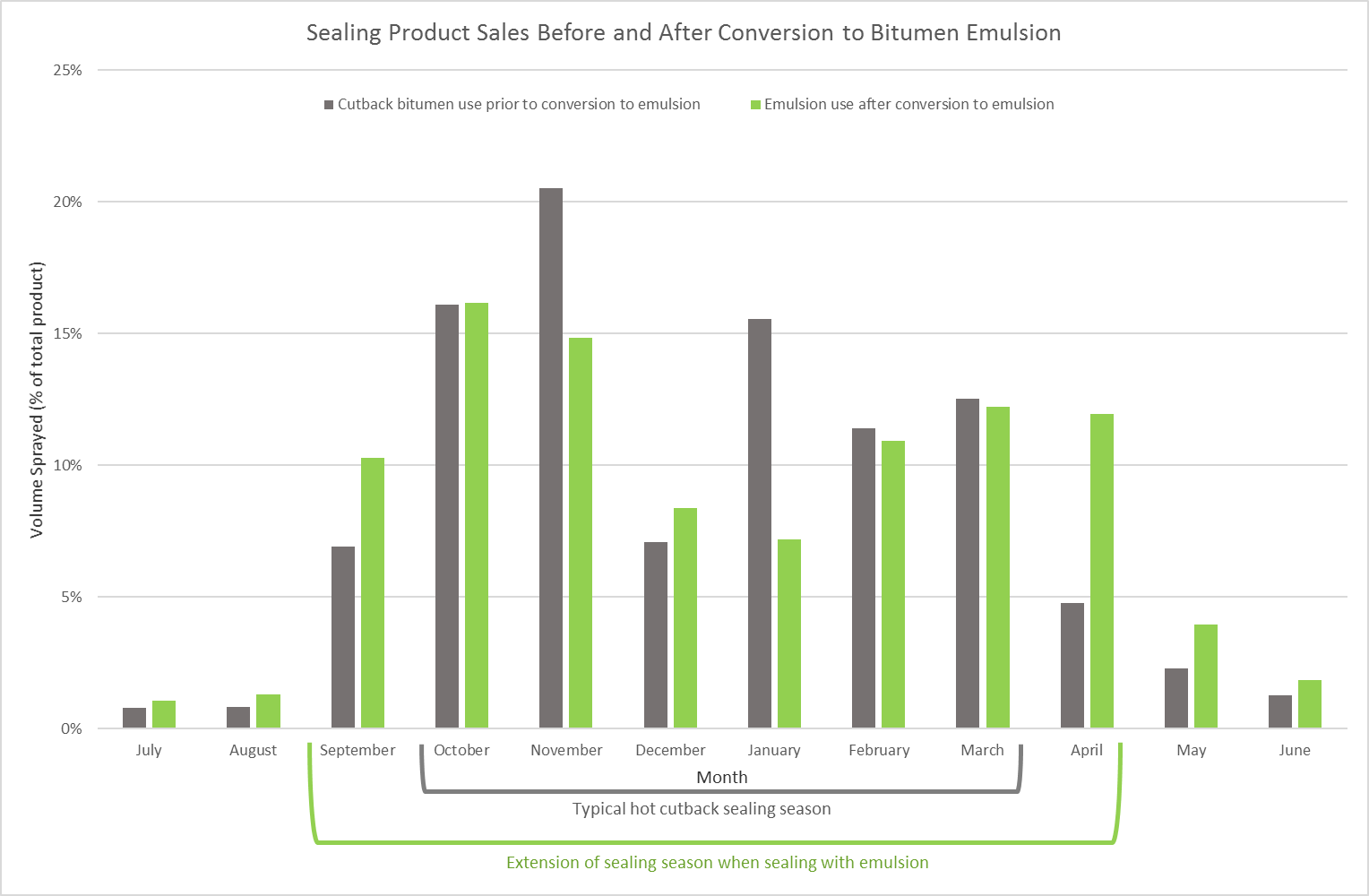

An example of this improved adhesion offered by bitumen emulsion can be seen in the change in behaviour of sealing crews when switching from cutback bitumen to emulsion. The Figure below shows the proportion of monthly bitumen volumes from a contract that previously sprayed 100% hot cutback bitumen compared to the volumes sprayed when the contract converted to 100% bitumen emulsion.

In New Zealand the traditional sealing season for hot cutback bitumen ends on 31st March as through experience, the risk associated with stripping using hot cutback bitumen becomes too great due to inclement weather. Bitumen sales volumes reduce dramatically after March when using hot cutback bitumen whereas bitumen emulsion sales remain at the same level as what was experienced during summer. A similar situation exists in September where hot cutback bitumen sales are lower than bitumen emulsion sales. In both cases it can be seen that the improved adhesion of bitumen emulsion allows crews to seal in colder conditions where the risk of stripping when using hot cutback bitumen would be too great.

Road Science has a range of world class emulsions available and technology able to assist you in selecting the correct one for your application. For any enquiries please contact the Road Science team.