Electrifying Change: Our Bluff Bitumen Plant's low-carbon journey

29 May 2025

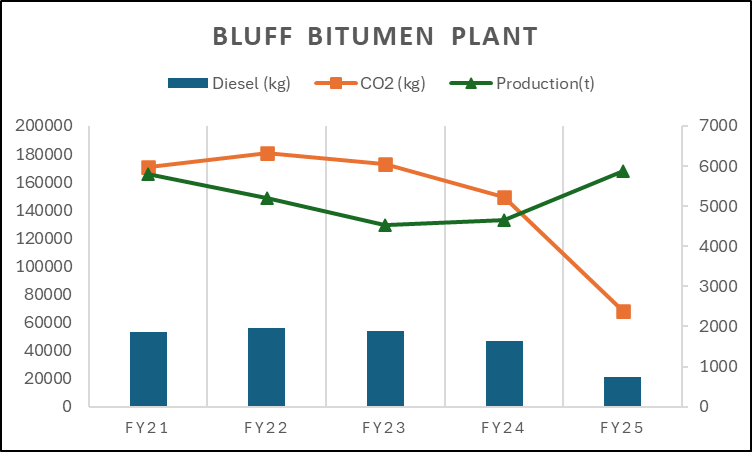

The future of bitumen is changing — and Road Science is leading the charge. With breakthrough technology and bold action, we’re showing that sustainability isn’t a distant goal — it’s happening now. In just eight months, our electric hybrid system at the Bluff Bitumen Plant has already cut carbon emissions by more than 60% — and we’re only getting started.

A milestone in carbon reduction

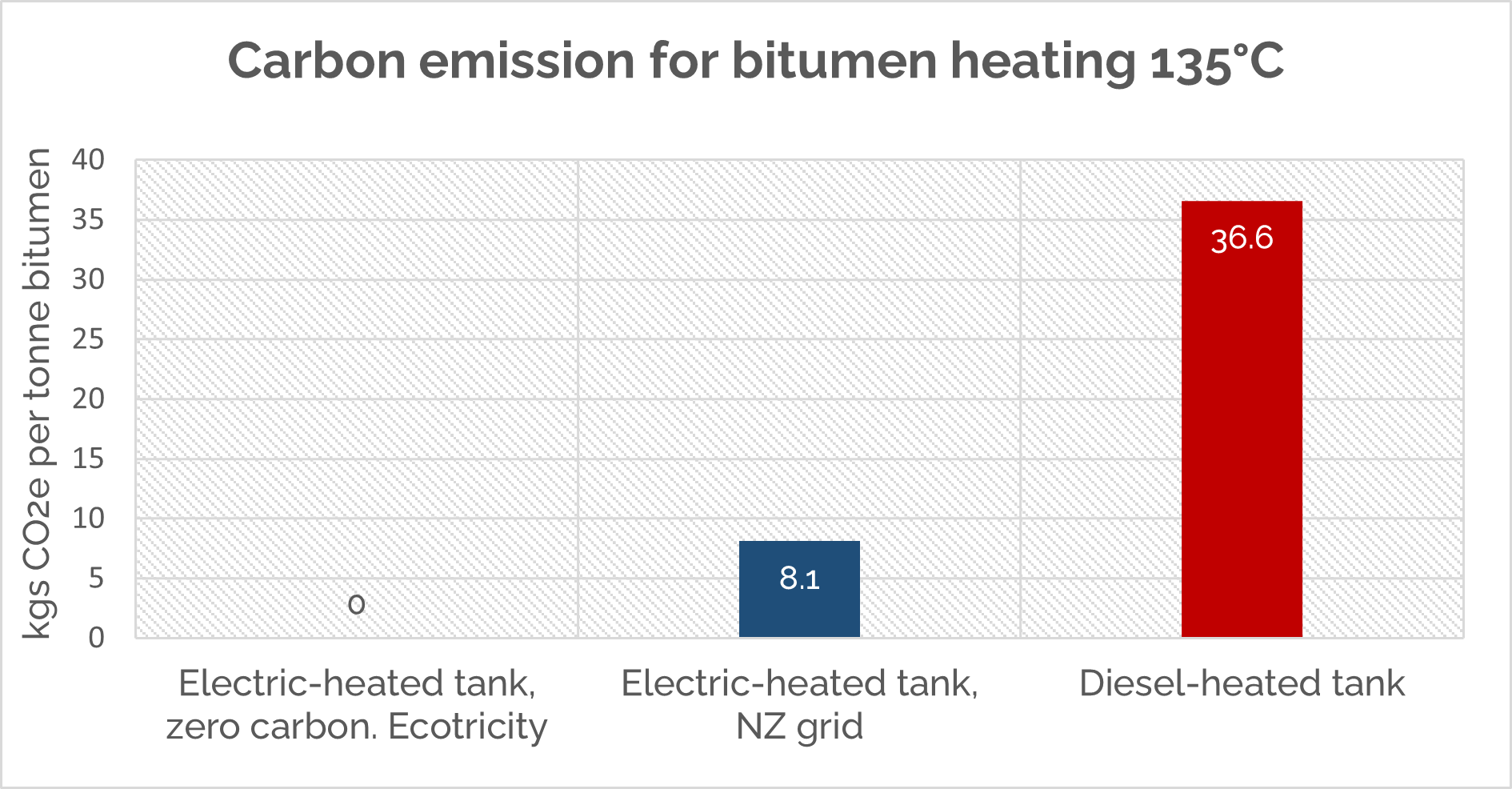

In September 2024, Road Science reached a major milestone in our sustainability journey with the commissioning of an electric hybrid heating system at our Bluff Bitumen Plant - a first-of-its-kind solution designed to overcome the limitations of traditional fossil fuel heating. Rather than relying on high-peak, on-demand heating, the system maintains bitumen at a steady 135°C using renewable electricity, reducing energy demand from 1.3 MW to just 200 kW. This shift was made possible through innovative tank redesign and enhanced insulation, and directly supports Waka Kotahi NZ Transport Agency’s low emission transport transition and aligns with New Zealand’s national target of carbon neutrality by 2050.

Over 60% emissions reduction achieved

In partnership with the Energy Efficiency & Conservation Authority (EECA) and with support from the Government Investment in Decarbonising Industry (GIDI) Fund, Road Science is leading the charge in industrial decarbonisation. Just eight months after launching our electric hybrid system, we’ve already cut carbon emissions by more than 60% — a strong early indicator of the system’s long-term potential. With less than a year of operation completed, this performance reinforces our ambition to operate a bitumen plant that produces zero operational GHG emissions. We are continuously monitoring and optimising the system to sustain and build on this momentum.

Smart technology for sustainable operations

The Bluff projects' electric hybrid system maintains the BB1 tank at 135°C while improving energy efficiency through enhanced insulation. A key outcome of this initiative was a significant reduction in energy use — cutting peak demand from 1.3 MW to just 200 kW. This not only ensures seamless integration with existing power supply but also presents a scalable model for other industries pursuing low-carbon solutions.

Transforming the industry: From hot cutback bitumen to bitumen emulsion

Road Science has long championed the transition from hot cutback bitumen to bitumen emulsion, and actively support the industry's current shift. This change is driven by the need for improved energy efficiency, reduced environmental impact, and enhanced worker safety.

Key Benefits:

- Energy Efficiency: Bitumen emulsion operates at ambient to 85°C — eliminating the need to rapidly heat materials to 180°C, as required for hot cutback bitumen. This reduces peak energy demand and supports the use of lower-intensity electric heating.

- Environmental Impact: Lower operating temperatures significantly reduce carbon emissions and facilitate the use of renewable electricity — helping meet low-carbon infrastructure goals.

- Worker Safety: Reduced temperatures minimise burn risks and lower exposure to harmful fumes, improving on-site health and safety.

Our plants are equipped to support this transition with seamless manufacture and delivery of bitumen emulsion products.

Building on success: The Lyttleton project

This Bluff initiative builds on the success of our low-carbon bulk bitumen tank in Lyttelton. In partnership with Energy NZ, we designed a state-of-the-art storage system that uses direct electric heating — completely eliminating the need for traditional diesel furnaces.

This system achieves an annual reduction of 209 tonnes of CO₂. And with our transition to 100% renewable electricity through Ecotricity, the energy used for heating in the Lyttelton tank can now be confidently considered zero carbon.

This initiative reinforces Road Science’s leadership in sustainable infrastructure and sets a new benchmark for low-emission industrial practices in New Zealand.

At Road Science, sustainability is at the heart of everything we do.

Through the continuous pursuit of low-carbon technologies and innovative practices, we’re not just responding to change — we’re leading it. Our commitment is helping to build a cleaner, more resilient future for New Zealand’s transport sector.